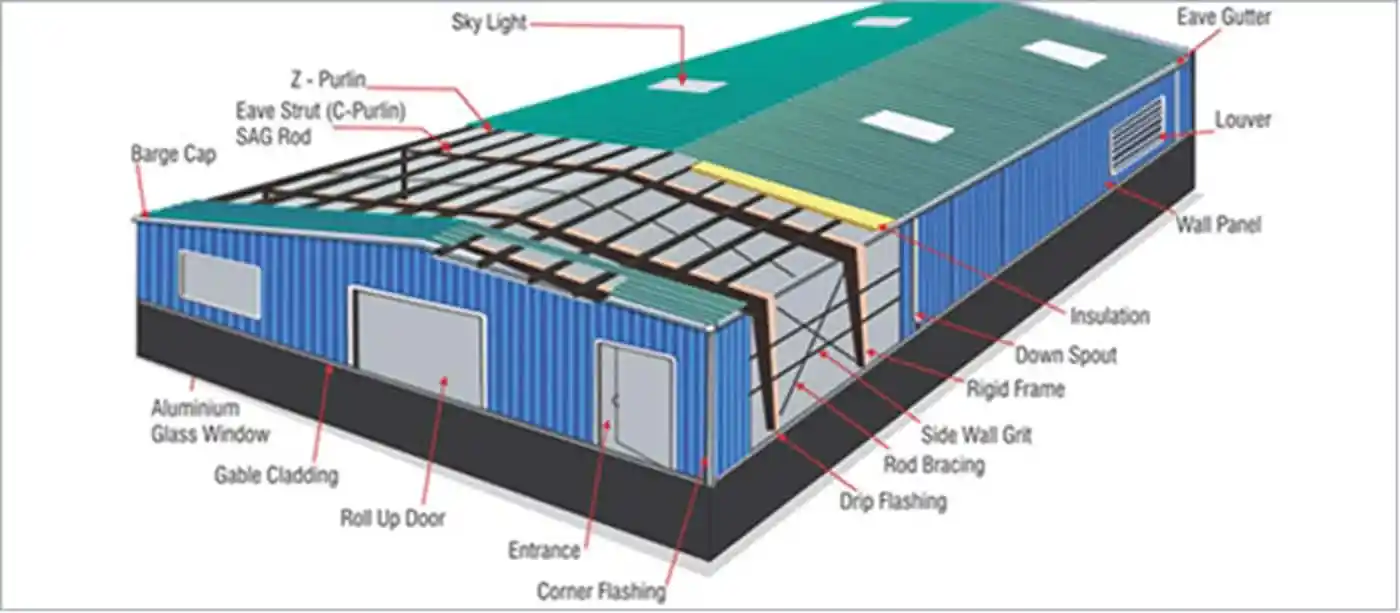

Pre Engineered Building (PEB) is a concept of structure having high structural strength, economical design while it supersedes the conventional fabrication, it lowers down the stress of foundation, hence there is less cost on civil construction as well.

Tailor made buildings based on client’s requirement and actual design calculations using tapered sections. An efficiently designed Pre Engineered Building (PEB) can be lighter than the conventional steel building by up to 30%.

BVM PREFAB is well equipped to produce Pre-Engineered Buildings (PEB structure) as per client’s requirements. The company has all the latest machinery to support this segment. The entire design of Columns, Rafters and other Accessories is based on international structural standards and invoice high technical welding and quality production.

These are the PEB structures basically manufactured/fabricated at the factory with the high tensile steel material by collecting complete information of shed/building (viz: Length, Width, Height etc.)

Tailor made buildings based on client’s requirement and actual design calculations using tapered sections. An efficiently designed Pre Engineered Building (PEB) can be lighter than the conventional steel building by up to 30%.

BVM PREFAB is well equipped to produce Pre-Engineered Buildings (PEB structure) as per client’s requirements. The company has all the latest machinery to support this segment. The entire design of Columns, Rafters and other Accessories is based on international structural standards and invoice high technical welding and quality production.

These are the PEB structures basically manufactured/fabricated at the factory with the high tensile steel material by collecting complete information of shed/building (viz: Length, Width, Height etc.)

Advantages of Pre-Engineered Buildings (PEBs):

- It is designed using international standards considering factors like weather conditions, wind Velocity, seismic zone etc. of the location.

- We design Energy Efficient buildings using skylight sheets, cladding louvers, Self-driven ventilators, Ridge vents, Roof Monitor design and many more.

- High aesthetic appeal using latest design of Gabble End, Curves, Bracket less Gutters etc.

- Flexibility in expansion.

- Saving in construction time.

OUR FACILITIES:

We have following Equipments to cater to manufacturing of Quality Pre-Engineered Building (PEB).

- Shear Machine: Automatic with tapper setting and length up to 6300 MM LONG and thickness up to 16mm of plates

- Shear Machine: Mechanical Shear Machine to cut up to 3000 mm and 2 mm thickness.

- SAW Machine : For quality welding

- MIG Welding : 05 MIG Welding Machine

- ARC Welding : 02 MIG Welding Machine

- Radial Drill : To drill up to 50 mm

- Magnetic Drill : To drill up to 50 mm in any angle

- Chaser Machine: To make foundation bolt, SAG Rods and Brace rods

- Power Press : 50 Tonne Power press to punch bend clits, Angles etc.

- PUG Cutting : To cut higher thickness by Gas

- Roll Forming : 02 nos. Roll Forming Machines to produce Hi RiB Profile sheets

- Roll Forming : 01 nos. Roll Forming to produce Sigma, “Z” and “C” Purlins.1 mm to 3 mm in thickness

- Crimping M/c. : To make NLC and curved sheets

- Press Break : To make Accessories like Gutter, Barge, Rack Angle, Down take etc.

- Folding Machine: To make accessories of any angle – Manual

- Mobile Crane : ACE make 14 tonne capacity mobile crane

- Total Area for production and storage is 50000 sq. ft with two overhead cranes of 5 tonne each.